Introduction to Repairing Sliding Window Rollers

Repairing sliding window rollers is a common maintenance task that can help ensure the smooth operation of your windows. Over time, the rollers can become worn out or damaged, leading to difficulties in opening and closing the window. Understanding how to repair sliding window rollers can save you money on professional repairs and prolong the life of your windows.

- Identifying the issue: The first step in repairing sliding window rollers is identifying the problem. This can involve checking for debris in the track, inspecting the rollers for signs of wear, or determining if the rollers need to be lubricated.

- Gathering the necessary tools: To repair sliding window rollers, you will typically need tools such as a screwdriver, pliers, and a putty knife. Having the right tools on hand can make the repair process easier and more efficient.

- Removing the window sash: In some cases, you may need to remove the window sash to access the rollers. This can involve carefully lifting the sash out of the frame and setting it aside in a safe place.

- Replacing the rollers: Once you have access to the rollers, you can remove the old rollers and install new ones. This may require adjusting the height of the rollers or ensuring they are properly aligned in the track.

- Testing the window: After replacing the rollers, it is essential to test the window to ensure it opens and closes smoothly. Make any necessary adjustments to the rollers or track to achieve optimal functionality.

By following these steps and taking the time to repair your sliding window rollers properly, you can maintain the functionality of your windows and avoid more significant issues down the line.

Understanding the Function of Sliding Window Rollers

Sliding window rollers play a crucial role in the smooth operation of sliding windows. Here are the key points to understand about the function of sliding window rollers:

- Supporting the Window Panels: Sliding window rollers are designed to support the weight of the window panels, allowing them to move along the track with ease. They help distribute the weight evenly, reducing the strain on the window frame.

- Facilitating Smooth Movement: The rollers are equipped with bearings that enable the windows to glide open and closed smoothly. This functionality is essential for effortless operation and preventing jams or sticking.

- Ensuring Stability: By providing stability to the window panels, the rollers help maintain proper alignment within the frame. This alignment is vital for a tight seal when the window is closed, enhancing energy efficiency and security.

- Adjusting for Wear and Tear: Over time, sliding window rollers may wear out due to frequent use or exposure to elements. Understanding their function helps in recognizing the signs of wear, such as grinding noises or difficulty in sliding the window, prompting timely maintenance or replacement.

- Compatibility with Tracks: Choosing the right rollers that are compatible with the window tracks is crucial for optimal performance. Different types of rollers are available, including single and double rollers, to suit various window designs and track configurations.

- Regular Maintenance: To ensure the longevity and efficiency of sliding window rollers, regular maintenance is necessary. Cleaning the tracks, lubricating the rollers, and inspecting for any damage are essential steps in preserving their function and extending their lifespan.

Understanding how sliding window rollers function is key to maintaining well-operating sliding windows and addressing any issues promptly. By comprehending their role in the window mechanism, homeowners can ensure smooth operation and prolong the life of their windows.

Identifying Common Issues with Sliding Window Rollers

- Sliding window rollers failing to move smoothly along the track may indicate a build-up of dirt and debris. This can cause friction and hinder the sliding motion.

- Uneven movement of the window or difficulty in opening and closing it can be signs of worn-out or damaged rollers.

- Squeaking or grinding noises when operating the window are often caused by rusted or corroded rollers.

- If the window tilts inward or outward when opened, it could suggest that the rollers are misaligned or improperly installed.

- Excessive vibration or wobbling of the window during operation may point to loose or damaged rollers that need replacement.

- In some cases, the rollers may completely detach from the window frame, preventing the window from moving at all.

Routinely inspecting the condition of the sliding window rollers is crucial to identify these common issues early on and prevent further damage to the window mechanism.

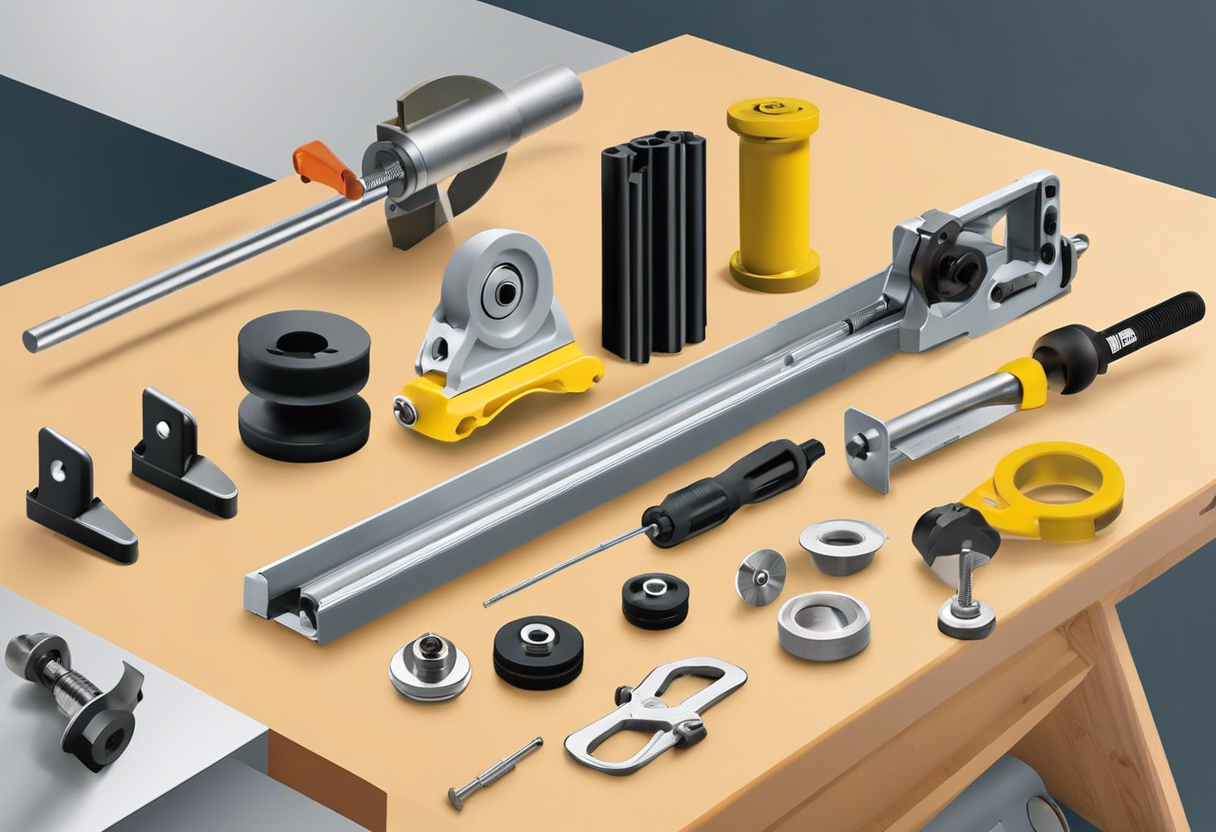

Tools and Materials Needed for Repairing Sliding Window Rollers

- Screwdriver

- Pliers

- Adjustable wrench

- Putty knife

- Safety glasses

- Gloves

- Replacement rollers

- Lubricant (such as silicone spray or WD-40)

- Cleaning solution (mild soap and water)

- Rag or cloth for cleaning

- Replacement screws (if necessary)

Before beginning the repair process, it is essential to gather all the necessary tools and materials. This ensures a smooth and efficient repair job on sliding window rollers.

Step-by-Step Guide to Removing Sliding Window Rollers

- Gather Your Tools: Before starting the repair process, ensure you have all the necessary tools such as a screwdriver, pliers, putty knife, and replacement rollers.

- Prepare the Window: To access the rollers, you need to remove the sliding window from the frame. Lift the window up and tilt it inward to make it easier to work on.

- Locate the Rollers: The rollers are usually located at the bottom of the sliding window. They are attached to adjustable carriages that allow for smooth movement.

- Remove the Old Rollers: Use a screwdriver to loosen the screws holding the rollers in place. Once the screws are removed, take out the old rollers carefully.

- Inspect the Rollers and Track: Check the condition of the rollers and the track they run on. Clean out any debris or dirt that may be causing the rollers to malfunction.

- Install the New Rollers: Insert the new rollers into the roller carriage and secure them in place by tightening the screws. Make sure the rollers are aligned properly for smooth operation.

- Test the Window: After installing the new rollers, reattach the sliding window to the frame. Test the window to ensure it moves smoothly along the track without any issues.

- Adjust if Necessary: If the window is not sliding correctly, adjust the rollers by turning the adjustment screw until the window moves smoothly.

- Finish Up: Once the window is functioning correctly, secure all screws, and clean any excess debris. Your sliding window should now be repaired and ready for use.

Follow these steps carefully to effectively remove and replace sliding window rollers for smooth and effortless operation.

Inspecting and Cleaning Sliding Window Rollers

Inspecting and cleaning sliding window rollers is an essential part of maintaining smooth functionality for your windows. Here are the steps to properly inspect and clean sliding window rollers:

- Remove the Sliding Window Panel: To access the rollers, start by removing the sliding window panel from the track. Carefully lift the panel up and out to avoid damaging the rollers.

- Examine the Rollers: Check the condition of the rollers for any signs of wear, dirt, or damage. Ensure that the rollers can still rotate freely and that there is no excessive buildup of debris.

- Clean the Rollers: Use a soft brush or cloth to clean the rollers and tracks. Remove any dirt, dust, or debris that may be affecting the movement of the rollers. You can use a mild detergent and water solution for stubborn dirt buildup.

- Lubricate the Rollers: After cleaning, apply a silicone-based lubricant to the rollers. This will help the rollers move smoothly along the tracks and prevent future issues with sticking or jams.

- Reassemble the Window Panel: Once the rollers are clean and lubricated, carefully place the window panel back into the track. Make sure it is properly aligned and slides smoothly along the track.

Regularly inspecting and cleaning sliding window rollers can prolong the life of your windows and prevent costly repairs in the future. By following these simple steps, you can ensure that your sliding windows continue to operate efficiently for years to come.

Replacing Damaged or Worn-Out Sliding Window Rollers

Sliding windows can become difficult to operate when the rollers are damaged or worn out. Here is a step-by-step guide to replacing them:

- Gather Tools: Before starting the replacement process, ensure you have the necessary tools such as a screwdriver, replacement rollers, and lubricant.

- Remove the Window Sash: Open the sliding window and carefully remove the sash by lifting it out of the frame.

- Access the Rollers: Locate the screws or clips holding the rollers in place. Use the screwdriver to remove them and access the rollers.

- Remove Old Rollers: Take out the old rollers by sliding them out of their brackets. Be cautious not to damage the window frame during this step.

- Install New Rollers: Insert the new rollers into the brackets, ensuring they are securely in place.

- Reattach the Rollers: Once the new rollers are installed, reattach any screws or clips that hold them in place.

- Lubricate the Rollers: To ensure smooth operation, apply lubricant to the new rollers. This will help reduce friction and extend the lifespan of the rollers.

- Replace the Window Sash: Carefully place the sash back into the frame by aligning it properly and sliding it back into place.

- Test the Window: Slide the window open and closed to test the new rollers. Ensure that the window moves smoothly along the track.

By following these steps, you can easily replace damaged or worn-out sliding window rollers and restore the functionality of your sliding windows.

Choosing the Right Replacement Rollers for Your Window

- Consider the Type of Window: Identify if you have a single or double-hung window, a sliding window, or a casement window. This will help you narrow down the type of replacement rollers you need.

- Measurements: Accurately measure the width, height, and depth of the existing rollers. Take note of any specific features like the shape of the roller or the type of mounting.

- Weight Capacity: Determine the weight of your window sash to ensure you choose replacement rollers that can support the load. This information is crucial for smooth and long-lasting operation.

- Material: Choose replacement rollers made from durable materials like nylon, steel, or brass. Consider the material of the existing rollers and opt for a similar or higher-quality material.

- Brand Compatibility: Some window brands may require specific replacement rollers. Check with the manufacturer or a professional to ensure you choose compatible rollers for your window.

- Ease of Installation: Select replacement rollers that come with clear installation instructions or consider hiring a professional for the replacement. Smooth installation can extend the lifespan of the rollers.

- Reviews and Recommendations: Read reviews from other customers or seek recommendations from professionals to determine the quality and performance of different replacement rollers brands.

- Budget: Set a budget for replacement rollers. While it is essential to choose quality rollers, there are options available at various price points to suit your needs.

Remember to prioritize quality and compatibility when selecting replacement rollers for your window to ensure smooth and efficient operation.

Installing New Sliding Window Rollers

When it comes to repairing sliding window rollers, one common issue is the need to install new rollers. Here is a detailed guide on how to correctly install new sliding window rollers:

- Gather the necessary tools: Before starting the installation, make sure you have all the required tools handy. These may include a screwdriver, pliers, a putty knife, and the new set of sliding window rollers.

- Remove the sliding panel: Begin by lifting the sliding panel up and out of the track. Be careful while doing this to avoid any damage to the window or injury to yourself.

- Access the rollers: Once the sliding panel is removed, locate the rollers at the bottom of the panel. In most cases, you will need to remove a cover or screen to access the rollers.

- Take out the old rollers: Use a screwdriver to carefully remove the screws holding the old rollers in place. Take note of how the old rollers are positioned so that you can install the new ones correctly.

- Install the new rollers: Position the new rollers in the same way the old ones were placed. Secure them by tightening the screws with a screwdriver.

- Reassemble the sliding panel: Once the new rollers are securely in place, slide the panel back into the track. Test the sliding motion to ensure that the new rollers are installed correctly and that the panel moves smoothly.

By following these steps carefully, you can successfully install new sliding window rollers and ensure the smooth operation of your sliding windows.

Adjusting and Testing the Newly Repaired Sliding Window

- Once the newly repaired sliding window rollers are installed, it is essential to ensure that they are adjusted correctly to operate smoothly.

- To adjust the sliding window, first, make sure that the sash is properly aligned within the frame. You can do this by adjusting the height of the rollers using a screwdriver.

- Turn the adjustment screws clockwise to raise the window and counterclockwise to lower it. Make small adjustments and test the window after each adjustment until it slides effortlessly.

- Check the window for any binding or sticking while opening or closing. If you notice any issues, fine-tune the adjustment screws until the window moves smoothly along the track.

- After adjusting the rollers, it is crucial to test the sliding window to ensure that it functions correctly. Open and close the window several times to verify its smooth operation.

- Listen for any unusual noises or resistance while moving the window. If you encounter any issues, revisit the adjustment screws and make necessary corrections.

- Additionally, check the locking mechanism of the sliding window to ensure that it secures properly when closed. Test the lock to guarantee that it engages and disengages smoothly.

- Finally, inspect the overall functionality of the sliding window to confirm that all components work harmoniously. Address any issues promptly to prevent further damage and ensure the longevity of the repair.

Maintaining and Lubricating Sliding Window Rollers for Longevity

Proper maintenance and lubrication of sliding window rollers are essential for ensuring their longevity and smooth operation. Follow these steps to keep your sliding windows in top condition:

- Regular Cleaning: Dirt, dust, and debris can accumulate on the rollers over time, causing them to become less efficient. Regularly clean the rollers using a soft brush or cloth to remove any buildup.

- Inspect for Damage: Periodically inspect the rollers for signs of wear or damage. Look for cracks, dents, or misalignment. If you notice any issues, consider replacing the rollers to prevent further damage.

- Lubrication: Apply a silicone-based lubricant to the rollers to ensure they continue to move smoothly along the track. Avoid using oil-based lubricants, as they can attract more dirt and debris.

- Adjustment: If your sliding window is not opening or closing smoothly, you may need to adjust the rollers. Refer to the manufacturer’s instructions for guidance on how to properly adjust the rollers for optimal performance.

- Track Cleaning: In addition to cleaning the rollers, make sure to also clean the track where the rollers glide. Use a vacuum or a damp cloth to remove any dirt or debris that may be causing friction.

- Avoid Force: Do not force your sliding window open or closed if it is not moving smoothly. This can put unnecessary strain on the rollers and tracks, leading to further damage.

Proper maintenance and lubrication of sliding window rollers are simple tasks that can greatly extend the lifespan of your windows. By following these steps regularly, you can ensure that your sliding windows continue to operate smoothly for years to come.

Preventive Measures to Avoid Sliding Window Roller Issues

- Regular Inspection: Inspect the condition of the sliding window rollers periodically to ensure they are functioning properly and are free from dirt or debris.

- Keep Tracks Clean: Regularly clean the tracks of the sliding windows to prevent the buildup of dirt and debris that can interfere with the smooth operation of the rollers.

- Lubrication: Apply lubricant to the rollers and tracks according to the manufacturer’s recommendations to reduce friction and wear on the components.

- Avoid Overloading: Be mindful of the weight limit when opening or closing the sliding window to prevent overloading the rollers.

- Handle with Care: Open and close the sliding window gently to avoid putting unnecessary strain on the rollers.

- Repair Issues Promptly: Address any issues with the sliding window rollers promptly to prevent further damage and avoid more costly repairs in the future.

- Professional Maintenance: Consider hiring a professional to perform routine maintenance on the sliding window rollers to ensure they are in optimal condition.

By following these preventive measures, homeowners can prolong the lifespan of their sliding window rollers and avoid potential issues that may arise from neglect or improper usage.

Safety Precautions When Repairing Sliding Window Rollers

- Wear Protective Gear: Always wear safety glasses and work gloves to protect your eyes and hands from debris or sharp edges while working on sliding window rollers.

- Ensure Stability: Work on a stable surface to prevent accidents. Use a sturdy ladder if working at heights to maintain balance and stability.

- Turn Off Power: If the window is motorized, make sure to turn off the power source to avoid any electrical accidents.

- Use Proper Tools: Use the correct tools for the job to prevent damage to the window or injury to yourself. Ensure tools are in good condition before use.

- Follow Manufacturer Instructions: Refer to the manufacturer’s guidelines for repairing the specific type of sliding window to ensure proper handling and safety measures.

- Check for Sharp Edges: Be cautious of any sharp edges on the window frame or rollers that could cause cuts or injuries. Handle with care.

- Work in a Well-Ventilated Area: Repairing sliding window rollers may involve using lubricants or cleaning solutions. Ensure proper ventilation to avoid inhaling fumes.

- Beware of Pinch Points: Be aware of pinch points on the window mechanism that could cause injury. Keep fingers and hands clear of moving parts.

- Seek Professional Help if Needed: If you are unsure of how to safely repair sliding window rollers, or if the repair seems complex, it’s best to seek professional assistance to prevent accidents or further damage.

By following these safety precautions, you can ensure a safe and successful repair of sliding window rollers.

Common Mistakes to Avoid When Repairing Sliding Window Rollers

- Using Incorrect Replacement Rollers: One common mistake to avoid when repairing sliding window rollers is using incorrect replacement rollers. It is crucial to ensure that the new rollers are the correct size and type for your particular window model.

- Neglecting Proper Cleaning and Lubrication: Another mistake to avoid is neglecting proper cleaning and lubrication of the rollers. Dirt and debris can accumulate in the rollers, causing them to malfunction. Regular cleaning and lubrication can help prevent this issue.

- Overlooking Other Components: When repairing sliding window rollers, it is essential to inspect and address any other components that may be contributing to the problem. This includes checking the track, frame, and any other moving parts to ensure everything is in good condition.

- Applying Excessive Force: Applying excessive force when trying to open or close a stubborn window can lead to further damage to the rollers. It is important to handle the window with care and avoid forcing it open or closed if it is not moving smoothly.

- Skipping Professional Help When Needed: Finally, one of the biggest mistakes to avoid is skipping professional help when needed. If you are unsure of how to properly repair the sliding window rollers or if the issue seems more complicated, it is best to seek the assistance of a professional to avoid causing further damage.

By avoiding these common mistakes, you can ensure a smoother and more successful repair process for your sliding window rollers.

Expert Tips and Tricks for Repairing Sliding Window Rollers

- Inspect the rollers regularly for signs of wear and tear such as flat spots or cracks to address issues promptly.

- Clean the rollers and tracks thoroughly to remove any dirt, debris, or grime that could impede smooth movement.

- Apply a silicone-based lubricant to the rollers to reduce friction and ensure effortless sliding.

- Adjust the height of the rollers using the adjustment screws to ensure proper alignment with the tracks.

- Replace damaged or worn-out rollers with high-quality replacements to restore the functionality of the sliding window.

- Use a screwdriver to adjust the tension of the rollers for a smoother opening and closing mechanism.

- Ensure that the tracks are properly aligned and securely fastened to prevent any disruptions in the sliding motion.

- Test the sliding window after repairs to confirm that the rollers are functioning correctly and the window moves smoothly along the tracks.

Remember, regular maintenance and timely repairs are essential to keep your sliding windows in optimal condition. By following these expert tips and tricks, you can effectively repair sliding window rollers and prolong the lifespan of your windows.

Benefits of Hiring a Professional for Sliding Window Roller Repair

- Expertise: Professionals have the knowledge and experience to accurately assess and fix sliding window roller issues, ensuring a successful repair.

- Quality Work: By hiring a professional, you can expect high-quality workmanship that will prolong the lifespan of your sliding window system.

- Time-Saving: Professionals work efficiently and effectively, saving you time and hassle compared to attempting repairs on your own.

- Proper Tools: Professionals have access to specialized tools and equipment needed for sliding window roller repair, ensuring a job well done.

- Long-Term Cost Savings: While there may be a cost associated with hiring a professional, the long-term savings from a job well done can outweigh the initial investment.

By entrusting your sliding window roller repair to a professional, you can enjoy peace of mind knowing that the job will be done correctly and efficiently.

Cost-Effective Ways to Repair Sliding Window Rollers on a Budget

- Cleaning and Lubricating: Clean the tracks and rollers thoroughly using a brush and soapy water. Once clean, apply a silicone-based lubricant to the rollers to ensure smooth movement.

- Adjusting the Rollers: Use a screwdriver to adjust the height of the rollers. This can help improve the alignment of the sliding window and make it easier to open and close.

- Replacing the Rollers: If cleaning and adjusting don’t solve the issue, consider replacing the rollers. Replacement rollers are affordable and can be found at most hardware stores. Remove the old rollers and install the new ones following the manufacturer’s instructions.

- DIY Repair Kits: Consider purchasing a DIY repair kit for sliding window rollers. These kits typically include replacement rollers and all the necessary tools for installation. They are a cost-effective option for fixing sliding windows on a budget.

- Professional Help: If the issue persists or if you are unsure about the repair process, consider hiring a professional to assess and fix the sliding window rollers. While this may incur some costs, it can save you time and ensure that the repair is done correctly.

By following these cost-effective repair methods, you can restore the functionality of your sliding window rollers without breaking the bank.

DIY vs. Professional Repair: What You Need to Know

When deciding between fixing sliding window rollers on your own or hiring a professional, consider the following points:

- Skill Level: A DIY approach requires a certain level of skill and knowledge about window mechanics. Professionals, on the other hand, are trained and experienced in handling various window repairs.

- Tools and Equipment: DIY repairs may necessitate investing in specific tools and equipment for the job. Professionals usually come equipped with the necessary tools to efficiently complete the repair.

- Time and Effort: Repairing sliding window rollers can be time-consuming, especially for those with limited experience. Professionals can often complete the task more quickly and with less effort on your part.

- Quality of Work: While a DIY repair can be a cost-effective solution, there is a risk of mistakes that could impact the functionality of the window. Professionals typically provide a guarantee on their work, ensuring quality results.

- Safety Concerns: Working on windows, especially those on higher floors, can pose safety risks for DIY enthusiasts. Professionals are trained to work safely at heights and minimize any potential hazards.

- Cost Consideration: DIY repairs can save money on labor costs, but if not done correctly, they may lead to additional expenses for fixing errors. Hiring a professional may initially cost more but can prevent future problems and ensure a job well done.

When in doubt, it is advisable to seek the assistance of a professional for repairing sliding window rollers, especially if you lack the necessary skills or tools. Professional repair not only ensures a quality outcome but also provides peace of mind knowing that the job is done safely and effectively.

Frequently Asked Questions About Sliding Window Roller Repair

- How do I know if my sliding window rollers need to be repaired? To determine if your sliding window rollers need repair, look out for signs such as difficulty in opening or closing the window, unusual grinding or scraping noises when operating the window, or visible damage to the rollers themselves.

- Can I repair sliding window rollers on my own? While some minor repairs can be done by homeowners, it is recommended to consult a professional for more complex issues. Attempting to repair rollers without proper knowledge or tools can lead to further damage.

- How long does it take to repair sliding window rollers? The time needed to repair sliding window rollers can vary depending on the extent of the damage and the expertise of the person performing the repair. Simple repairs may take a few hours, while more complex issues could require a day or two.

- What tools are required to repair sliding window rollers? Common tools needed for sliding window roller repair include a screwdriver, pliers, putty knife, lubricant, replacement rollers, and possibly a hammer. It’s important to have the right tools to ensure a successful repair.

- How often should sliding window rollers be replaced? Sliding window rollers typically need to be replaced every 5-10 years, depending on usage and maintenance. Regular cleaning and lubrication can help extend the lifespan of the rollers.

- Are there different types of sliding window rollers? Yes, there are various types of sliding window rollers, including single-wheel rollers, dual-wheel rollers, and adjustable rollers. It’s essential to identify the specific type of roller in your window before attempting a repair.

- What is the cost of repairing sliding window rollers? The cost of repairing sliding window rollers can vary based on factors such as the extent of the damage, the type of rollers, and whether professional help is required. On average, repairs can range from $50 to $200 per window.

Conclusion and Final Thoughts

- Proper maintenance of sliding window rollers is crucial for smooth and efficient operation.

- Regular cleaning and lubrication can prevent issues such as jamming and difficulty in opening or closing the window.

- When facing problems with sliding window rollers, it is essential to identify the root cause before attempting any repairs.

- Replacing damaged or worn-out rollers with high-quality replacements is key to ensuring the longevity of your sliding windows.

- Seeking professional help for complex roller repairs can save time and prevent further damage to the window mechanism.

- By following the steps outlined in this guide, individuals can successfully repair their sliding window rollers and restore functionality to their windows.

- Remember to test the window after repairs to ensure that it opens and closes smoothly.

“By maintaining sliding window rollers properly, homeowners can prolong the life of their windows and avoid costly replacements in the future.”

“Regular inspection and timely repairs can help prevent minor issues from snowballing into major problems with sliding window rollers.”